2 of 2 Product variants

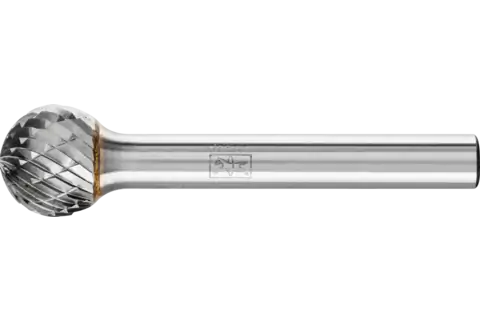

| Item number / EAN | Cut | Dia. external | Dia. shank | Length, cut | Length, total |

PU

|

Please login to see the price |

|---|---|---|---|---|---|---|---|

|

21000054 / 4007220955383

|

TOUGH | 8 mm | 6 mm | 7 mm | 47 mm | 1 piece | Login / Register |

|

21000056 / 4007220770160

|

TOUGH | 12 mm | 6 mm | 10 mm | 51 mm | 1 piece | Login / Register |